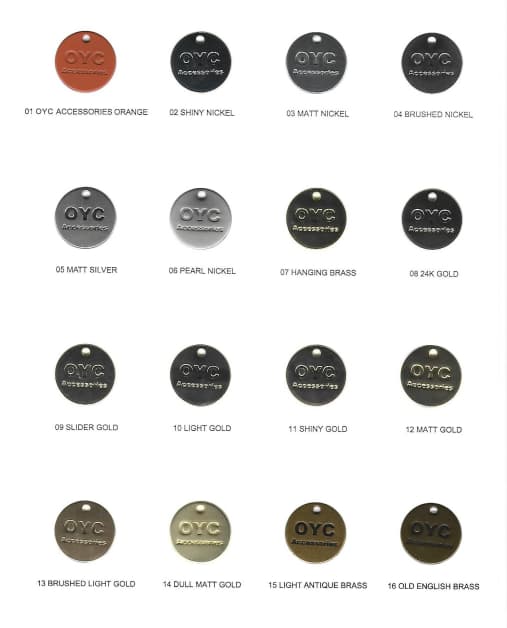

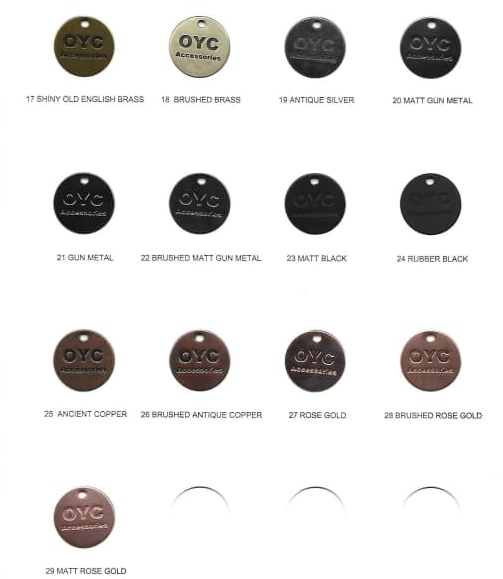

- Personalized Customization High Quality Metal Accessories For Brand

- Contact +86-13924451472

Product Details

- Temperature resistance and weather resistance

Performance of electrophoretic layer: Usually the temperature resistance ranges from -40℃ to 150℃, and the short-term temperature resistance can reach 200℃, which is suitable for extreme environment.

Synergistic effect of the frame: Weather-resistant frame can resist UV rays, ozone, temperature and humidity changes, and slow down the aging of the coating, ensuring that the Logo maintains the consistency of appearance for a long time. - Electrical properties (if applicable)

Insulation: The electrophoretic coating is an insulating material with volume resistivity usually ≥10¹² Ω-cm, which is suitable for the electrical isolation needs of electronic equipment Logo.

Influence of lattice frame: Transparent lattice frames do not change the insulating properties while providing mechanical protection. - Environmental protection and safety

Advantage of electrophoresis process: Water-based electrophoresis coatings have low VOC emission and comply with RoHS and other environmental standards, which is suitable for consumer electronics and other areas with high environmental requirements.

Choice of cradle: It is recommended to use environmentally friendly cradle (e.g. UV curing cradle) to further reduce the release of harmful substances.

Technical Recommendations

Coating thickness control: The thickness of the electrophoresis layer is recommended to be 15-25μm, and the thickness of the lattice frame is recommended to be 5-10μm, in order to balance the performance and cost.

Curing process: The electrophoresis layer should be cured at 180-200°C for 20-30 minutes, and the lattice frame can be UV cured or heat cured (150°C/30 minutes), depending on the type of coating.

Test verification: Salt spray test (≥500 hours), artificial accelerated ageing (QUV ≥1000 hours) and adhesion test are recommended to verify the performance.

Summary

‘Engraved Round Metal Logo Electrophoresis Lattice Frame’ achieves high corrosion resistance, abrasion resistance and aesthetics through the composite process of electrophoresis and lattice frame, and is suitable for high-quality marking needs in automotive, electronics, home appliances and other fields. The actual performance needs to be adjusted according to the specific coating formula and process parameters, and it is recommended to cooperate with the supplier to optimise the process.

相关推荐

Serach

Related recommendations

© 2025. All Rights Reserved. OYC Accessories CO.,LTD