- Personalized Customization High Quality Bag Hardware/Metal Accessories For Brand

- Contact +86-13924451472

Product Details

- Processing and molding

Forming Difficulty: Higher hardness coatings may be more prone to cracking or peeling during processing (e.g., stamping, bending, etc.), and coating formulations and processes need to be optimized to balance hardness and flexibility.

Process adjustment: For specific hardness requirements, electrophoresis process parameters (e.g. voltage, time, temperature, etc.) need to be adjusted to ensure a balance between coating performance and processability.

- Environmental Adaptation

Temperature and humidity: Higher hardness coatings are more stable in high temperature or high humidity environments, and are less likely to soften or deform, making them suitable for brand labels used outdoors or in harsh environments.

UV resistance: Some of the higher hardness coatings have better UV resistance, which prevents brand labels from fading or aging in the sun. - Cost and Productivity

Material cost: High-hardness coating materials can be costly and should be selected based on brand positioning and budget.

Production efficiency: Optimizing the electrophoresis process can improve production efficiency, but high hardness requirements may make the process more difficult, so cost and performance need to be weighed.

Recommendations

Hardness selection: Select the appropriate hardness range according to the usage scenario and functional requirements of the brand label. For example, high-end brand labels can choose a high hardness coating to enhance texture, while labels for daily necessities can moderately reduce hardness to optimize processability.

Process optimization: By adjusting the electrophoresis process parameters (e.g. voltage, time, temperature, etc.), a balance between hardness and coating performance is achieved.

Testing and verification: Before mass production, conduct sufficient performance tests (e.g., abrasion resistance, corrosion resistance, adhesion, etc.) to ensure that the coating meets the usage requirements of brand labels.

Summarize

Hardness is one of the key factors affecting the performance of electrophoretic lattice frame for brand labels. By reasonably controlling the hardness, the abrasion resistance, corrosion resistance, surface gloss and texture of brand labels can be significantly improved, and at the same time, it is necessary to balance the relationship between hardness, processability and cost to meet the needs of different application scenarios.

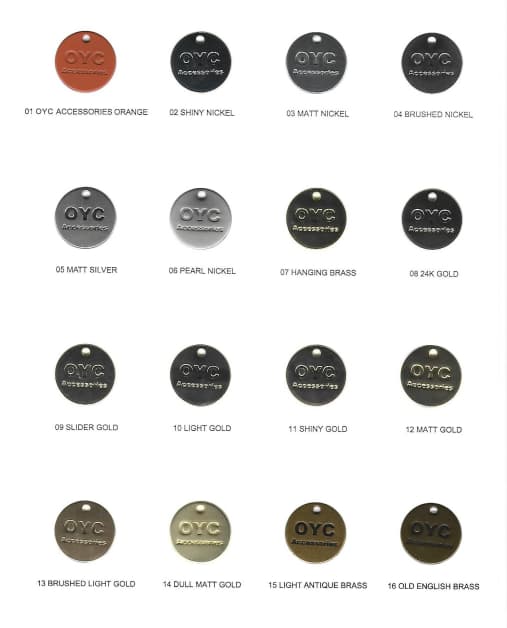

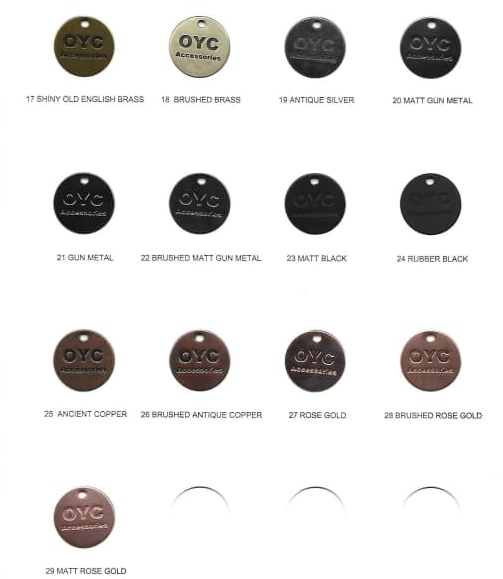

oyc

High Quality metal fitting, Dog Hook, Metal Ring,customer made Logo Plate

Related Bag Hardware

Serach

Hot Tags

Engraved Round Metal Logo Metal Bag Snap Hook 2 Holes Sewing Design Metal Plate Round Metal Tag Logo Metal Snap Gate O Ring Metal Name Tags Logos for Bags Wallet Double Pin Buckle Metal Bag Buckle Handbag Logo Metal Metal Plates Brand Logos Adjustable Slider Buckle Zinc Alloy Turn Lock Custom Rivet With Logo Logo Metal Plate Embossed Metal Plate Twist Turn Buck Lock

© 2025. All Rights Reserved. OYC Accessories CO.,LTD