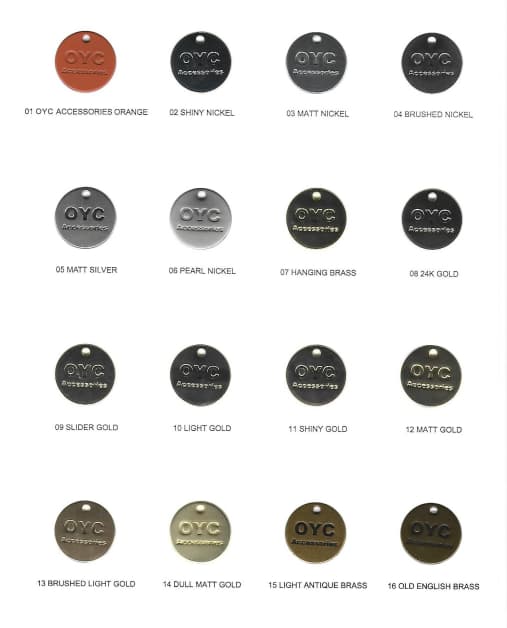

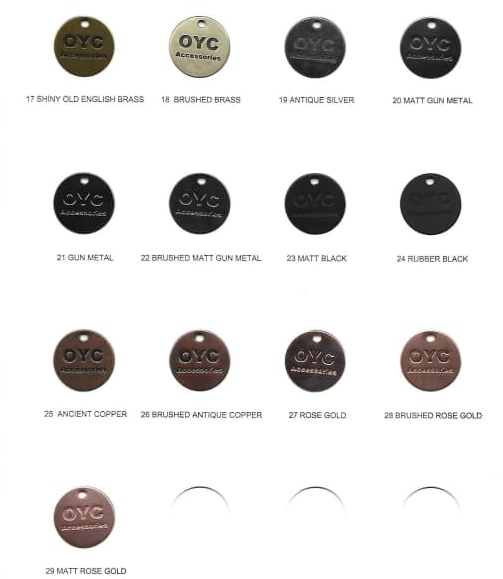

- Personalized Customization High Quality Metal Accessories For Brand

- Contact +86-13924451472

Product Details

- Integrated impact analysis

Performance synergy:

The combination of hardness, electrophoresis and lacquering processes can significantly enhance the overall performance of the sign. The hardness provides basic strength, the electrophoresis provides corrosion resistance and adhesion guarantee, and the lattice frame further improves abrasion resistance and decorative properties.

Application Scenarios:

Industrial signage: high hardness, corrosion resistance and abrasion resistance are required, high hardness base material + electrophoretic coating is recommended.

High-end decorative signage: high gloss and corrosion resistance, electrophoresis priming + racking process is recommended.

Outdoor signage: Long-term weathering resistance is required, electrophoretic coating + racking process is recommended, and good weathering resistant paint is selected.

Cost and process trade-off:

The cost of lattice process is high, if the budget is limited, only electrophoresis process can be used; if the requirements for decorative and abrasion resistance are very high, then the combination of lattice process is needed. - Recommended solutions

Base programme:

High hardness metal substrate (e.g. stainless steel) + electrophoretic coating, suitable for most industrial and outdoor scenarios, cost-effective.

High-end solution:

High hardness metal substrate + electrophoretic coating + racking process, suitable for high-end decorative signs, combining performance and aesthetics.

Special requirements programme:

According to the specific environment (e.g. high salt fog, high temperature, etc.), we can choose special coatings or processes, such as salt fog-resistant electrophoretic coating or high-temperature lattice process.

相关推荐

Serach

Related recommendations

© 2025. All Rights Reserved. OYC Accessories CO.,LTD