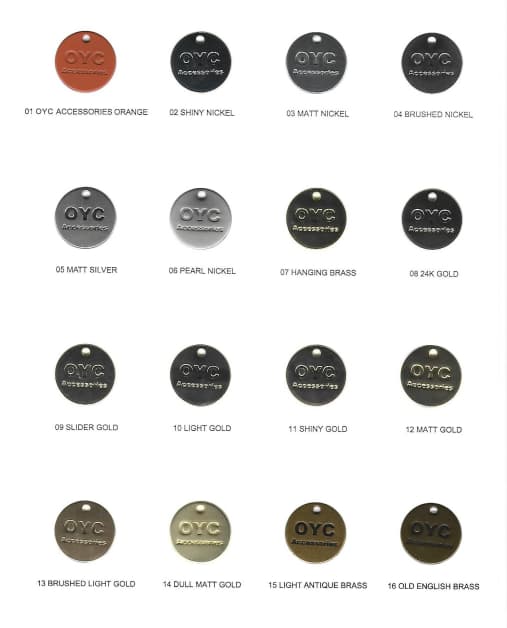

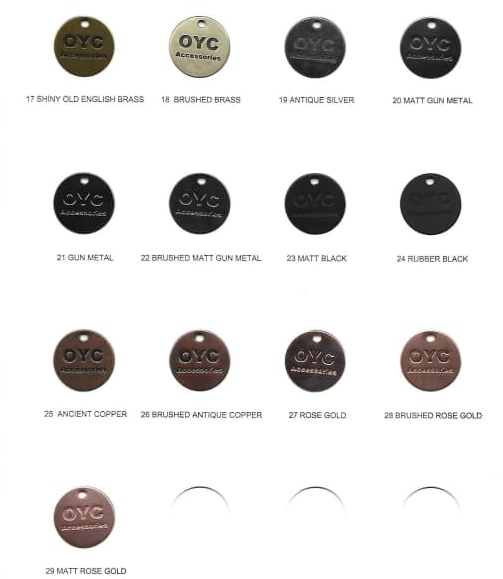

Physical properties of brand tag’s electrophoretic lattice frame

The “Brand tag” electrophoresis lattice is not a widely recognized or standardized product name. In common industry terminology, electrophoresis and lattice (often referred to as a sealer or topcoat) are two different surface treatments that may be combined for specific products, but there is a lack of publicly available technical information that directly corresponds to the “Brand tag” electrophoresis lattice. However, there is a lack of publicly available technical information that directly corresponds to the “Brand tag electrophoresis lattice”. The following provides a framework for analyzing the physical properties of electrophoresis and lacquering processes: First. physical properties of electrophoresis processElectrophoretic coating causes charged particles to be deposited on the surface of the workpiece through the action of an electric field, forming a uniform coating, and its physical properties include: Coating uniformity: electrophoresis can realize uniform coverage of the inner cavities and crevices of complex workpieces, avoiding dead corners.Adhesion: dense paint film, strong bonding with substrate, excellent impact resistance.Corrosion resistance: dense coating, salt spray resistance test can reach more than 72 hours, suitable for high corrosion resistance requirement scene.Mechanical properties: high hardness (such as 180 ℃ baking hardness up to 4-5H), strong impact resistance.Glossiness: By adjusting the ratio of high-gloss/low-gloss paint, different gloss requirements can be realized.Second, the physical properties of the lattice frame (closed paint / top coat) processLattice frame is usually used as a surface protection layer, its physical properties include:Weathering resistance: to prevent the underlying plating layer from oxidizing and discoloring, and to enhance the corrosion resistance.Hardness and abrasion resistance: Provide surface hardness to resist scratches and abrasions.Adhesion:…