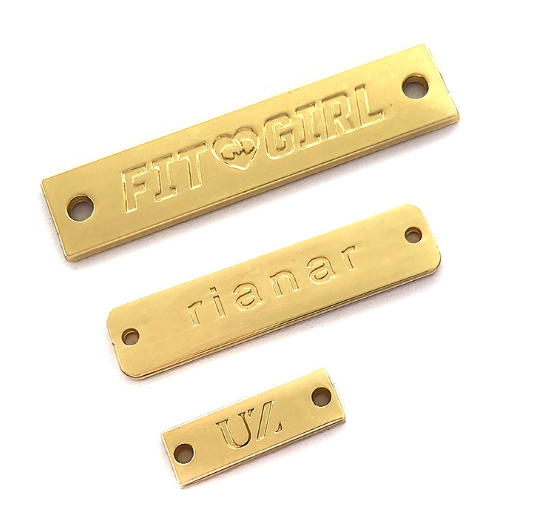

- Personalized Customization High Quality Metal Accessories For Brand

- Contact +86-13924451472

Product Details

- Weather resistance

Ultraviolet stability: the spray oil layer needs to have good UV resistance to prevent yellowing and chalking. Adding UV absorber can prolong the service life.

Temperature Adaptability: The plating and sprayed layer should be able to withstand high (e.g. 80°C) and low (e.g. -20°C) temperatures to avoid cracking due to thermal expansion and contraction.

Testing standards: QUV accelerated weathering test (ASTM G154) or damp heat cycle test (ISO 6270-2) is required. - Optical Properties

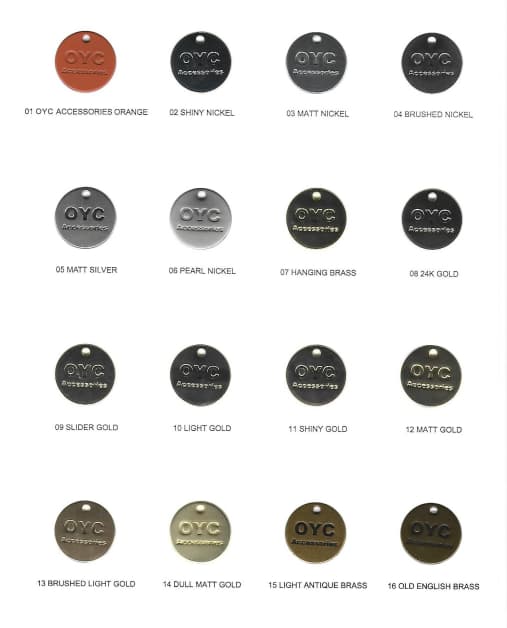

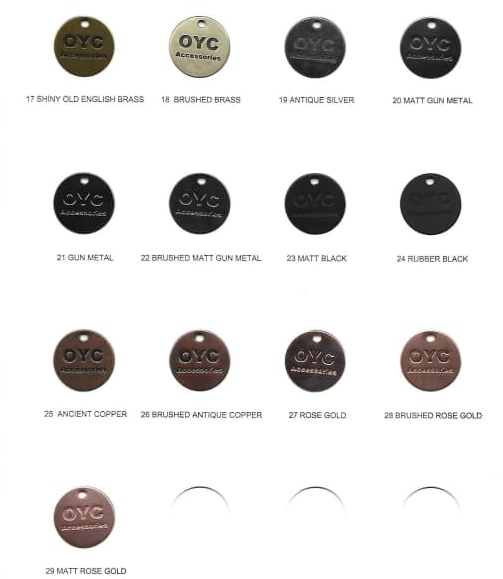

Gloss: Plating (e.g. chrome) has high reflectivity and the gloss of the sprayed layer can be adjusted with matte, semi-gloss or high-gloss coatings.

Color consistency: The color of the oil-sprayed layer needs to be coordinated with the plating layer to avoid color difference.

Transparency: For signage that requires light transmission (e.g., backlit logo), transparent spray material should be selected. - Electrical properties

Conductivity: plating layer (such as gold, copper) has good electrical conductivity, suitable for electronic labels or the need for electrostatic shielding of the scene.

Insulation: the oil spraying layer is an insulating material, which can prevent the plating layer from short-circuit or leakage. - Mechanical properties

Impact resistance: the oil spray layer can absorb the impact energy and prevent the plating layer from peeling off.

Scratch resistance: The combination of hard plating layer and high hardness oil spray layer provides excellent scratch resistance. - Environmental Adaptability

Chemical resistance: Signage may come into contact with chemicals such as acids, alkalis, solvents, etc. Chemical resistant plating and oil spraying materials need to be selected.

Salt spray resistance: suitable for marine or high humidity environment, need to be verified by salt spray test.

Optimization Suggestions

Material Selection: Select the appropriate plating and oil spraying materials according to the application scenario. For example, outdoor signage is recommended to use UV coating and hard plating with excellent weather resistance.

Process control: Strictly control the process parameters of plating and spraying (e.g. thickness, temperature, time) to ensure that the performance meets the standard.

Test verification: Evaluate the long-term reliability of the signage through accelerated tests that simulate the actual use environment.

Through rational design and process control, the plated and oiled Brand tag can be aesthetically pleasing, durable and functional to meet the needs of high-end brand identity.

Tags: logo plate

相关推荐

Serach

Related recommendations

© 2025. All Rights Reserved. OYC Accessories CO.,LTD