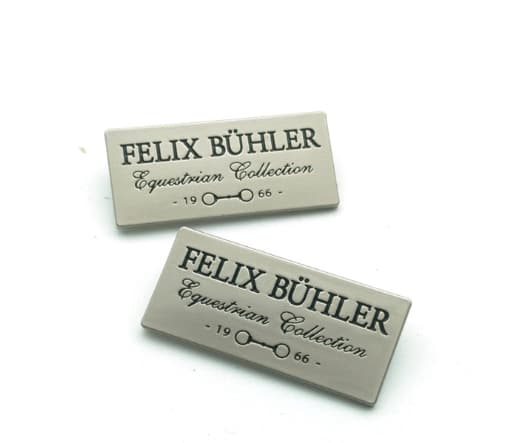

- Personalized Customization High Quality Metal Accessories For Brand

- Contact +86-13924451472

Hardness of electrophoretic lattice frame of Brand Tag

The “Brand Tag” is not a generic or well-known brand name in the field of electrophoresis lattice racks, so it is not possible to provide hardness data for this brand of electrophoresis lattice racks directly. However, it is possible to describe the hardness properties of electrophoretic laths based on their general technical characteristics.

First,general information on the hardness of electrophoretic laths

The hardness properties of electrophoretic laths, which are formed by depositing a resin coating on metal surfaces through the electrophoretic process, are usually characterized as follows:

Wide range of hardness: The hardness of electrophoretic lath is generally between 2H – 5H, depending on the type of resin used, the curing process and the adjustment of the formulation. For example, higher hardness can be obtained by using epoxy or polyurethane resins with a high degree of cross-linking and curing at high temperatures.

Hardness correlates with abrasion resistance: Higher hardness usually means better abrasion resistance, which resists scratches and abrasions from daily use and extends the life of the coating.

Adjustable hardness: By adjusting the formulation of the electrophoresis solution (e.g. resin concentration, proportion of hardener, etc.) and the parameters of the electrophoresis process (e.g. voltage, time, temperature, etc.), the hardness of the coating can be adjusted within a certain range to meet different application requirements.

Second.factors affecting the hardness of electrophoresis coating

Resin type: Different types of resins have different molecular structures and performance characteristics, which have a significant effect on the hardness of the coating. For example, epoxy resin coatings usually have high hardness and good adhesion, while polyurethane resin coatings may have better flexibility and chemical resistance.

Curing process: The curing temperature, time and method (e.g., heat curing, UV curing, etc.) affects the degree of cross-linking of the resin and therefore the hardness of the coating. Higher curing temperatures and longer curing times are usually favorable to increase the hardness of the coating.

Additives: Adding appropriate amounts of fillers (e.g., silica, alumina, etc.) or additives (e.g., leveling agents, defoamers, etc.) to the electrophoresis solution can improve the properties of the coating, including the hardness. Fillers can increase the denseness and hardness of the coating, while additives can optimize the construction performance and appearance quality of the coating.

Third.how to choose the right electrophoretic lattice frame

Define application requirements: Determine the required coating hardness range based on the product’s usage environment and performance requirements. For example, for products that require high abrasion resistance, a higher hardness electrophoresis lattice should be selected.

Understand the product performance: Ask the supplier for the technical data of the product to understand its hardness, adhesion, corrosion resistance, weather resistance and other performance indexes, and make a comparative analysis.

Conduct sample tests: Test the samples under actual application conditions to assess whether the performance of the coating meets the requirements. For example, abrasion resistance test, chemical resistance test, etc. can be conducted.

Consider cost and process: When selecting electrophoretic lattice, it is also necessary to consider the cost and feasibility of the process. For example, some high-performance electrophoresis laths may be more expensive or require special curing equipment, which requires a trade-off between performance and cost.

相关推荐

- Wholesale Diy Accessories 13mm Snap Clasp 19mm Chic Silver Snap Hook Clasp 22mm Modern Zinc Alloy Swivel Hooks for Handbag Bags

- Bag Hardware Custom Snap Hook Diy Accessories 13mm Strap Purse Clasp Gold Silver 10mm Keychain Swivel Snap Hook for Bag Making

- Temperature of engraved round metal logo spray lattice oil

- The abrasion resistance of engraved round metal logo-B

- Hardness of electrophoretic lattice frame of engraved round metal logo-A

© 2025. All Rights Reserved. OYC Accessories CO.,LTD